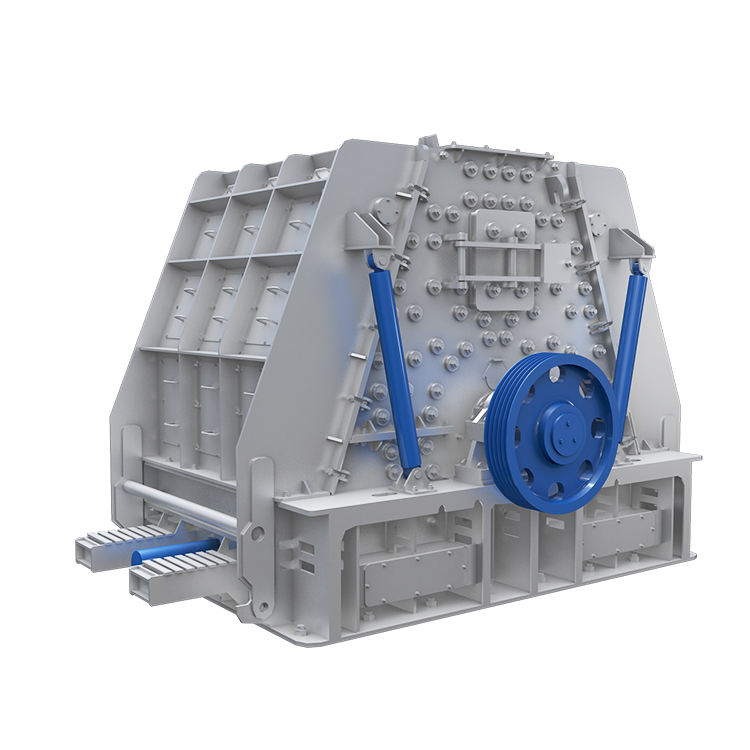

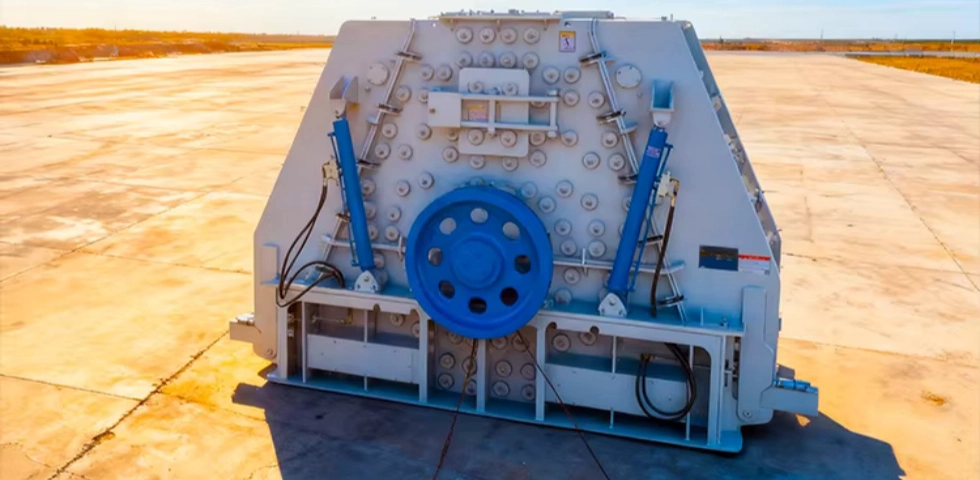

Double-chamber Hard Rock Crusher

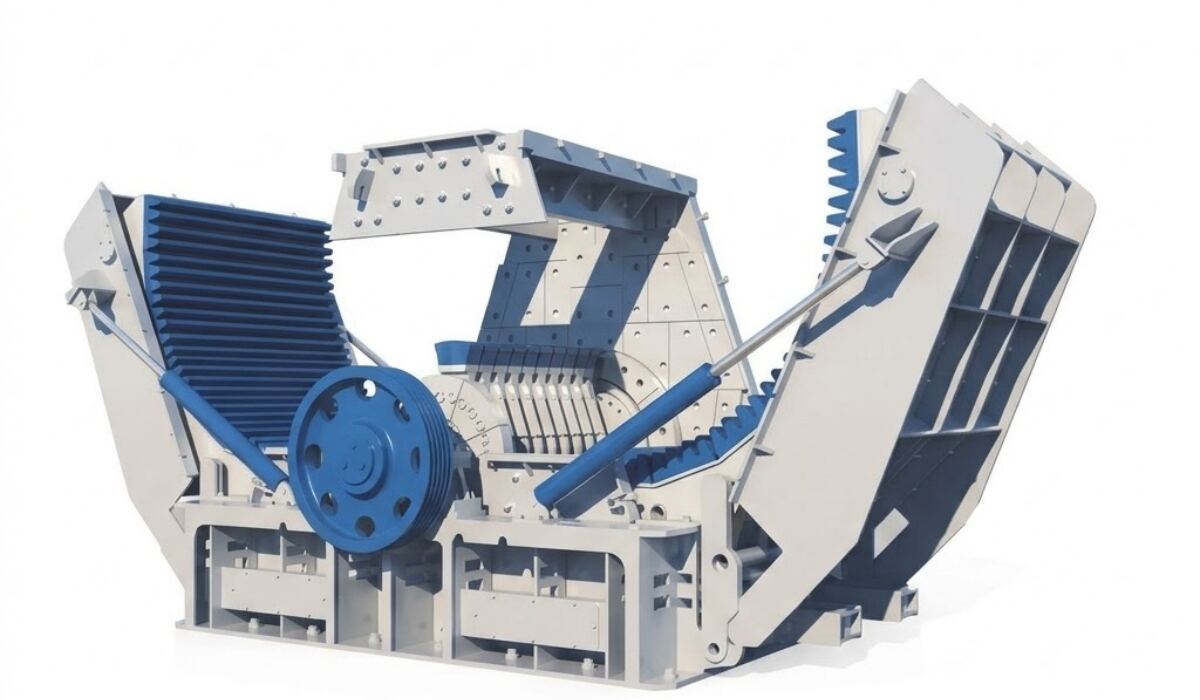

Rotor Assembly

The entire rotor is equipped with a wear-resistant sheath to protect the rotor body from wear and ensure stable equipment operation.

Counterattack Liner Assembly

Made of high-chromium molybdenum alloy wear-resistant material, the reinforced version is more durable.

Hydraulic Opening Assembly

Fully exposes the interior of the equipment cavity, facilitating maintenance and replacement of parts.