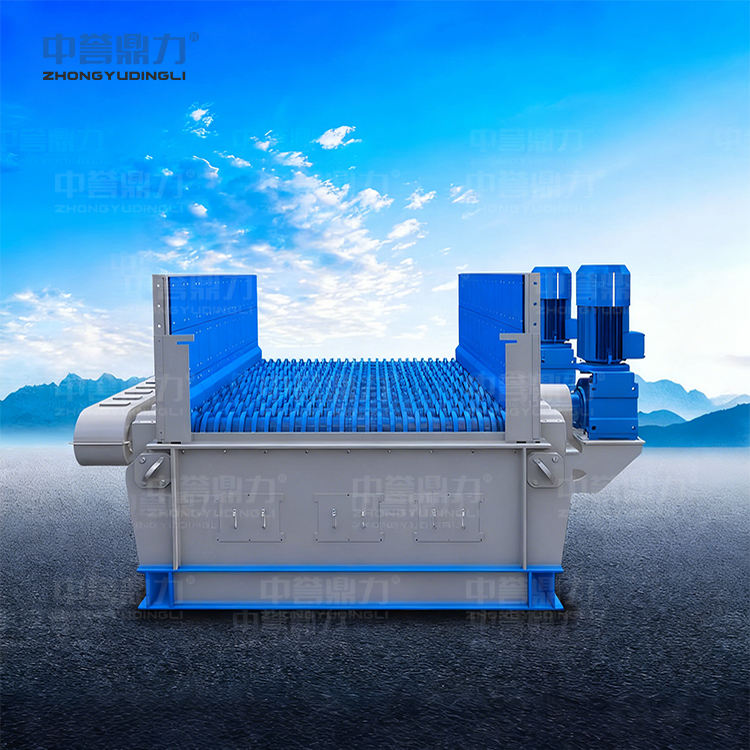

The Roller Screen Separator, also known as a roller screen or mud-rock separator, is designed for dry screening of coarse materials, separating mud and rocks without water. Zhongyu Dingli roller screens offer stable operation, high separation efficiency, and large processing capacity.

Applicable Materials: Mud-rock mixtures, construction waste, slag, soil and rock mixtures

Max Feed Size: ≤ 800 mm

Capacity: 500–1900 t/h

This equipment effectively separates mud and stones while also serving as a feeder, offering multiple functions in one machine and saving on equipment investment.

The roller screen consists of a housing, bearing seats, chains, sprockets, rollers, roller plates, and a motor.

Conact Us

A roller screen separator is used for dry screening of coarse materials, mainly for separating mud and rocks without adding water. It is commonly applied in aggregate production and material pretreatment stages.

The roller screen is suitable for mud-rock mixtures, construction waste, slag, soil and rock mixtures, and other coarse, mixed materials.

The machine uses rotating rollers driven by chains and sprockets. Fine materials fall through the gaps between rollers, while larger stones move to the end of the screen and are discharged, achieving efficient mud-rock separation.

The roller screen offers stable operation, high separation efficiency, and strong durability. It supports dry screening, is not easy to clog, and can also serve as a feeding device, reducing overall equipment investment.

Yes. The spacing between rollers can be customized based on material size and screening requirements. The equipment can be installed horizontally or at an incline to match different production line layouts.

Yes. Please feel free to contact us.

Budweiser Ave, Tangzhuang Town, Weihui City, Xinxiang, Henan, China

+86-18827272727

Welcome your inquiry, we will reply you within 12 hours after receiving the email