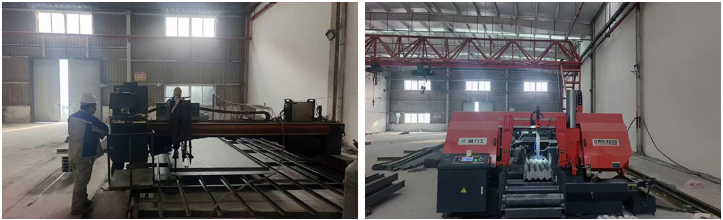

Ensure the timely and precise completion of the 3YKZ3680 vibrating screen production for the Chongqing project, adhering to the established plan. Guarantee the delivery of products that meet the highest quality standards and are delivered in a timely manner..

The new project in Chongqing Beichuan is starting, and we are preparing to support production in advance. We are responding quickly to project demands, effectively shortening the product delivery cycle, and better serving the project construction.

The business manager collaborated with Shanxi Yangquan, Hubei Xiaochang, and Shanxi Hejin on the project, conducting on-site aerial surveys, and engaging in in-depth communication and technology solution exchange with customers. The department also organized the 2024 annual debriefing summary meeting, selected recommended advanced materials, and mobilized the annual meeting program preparation.

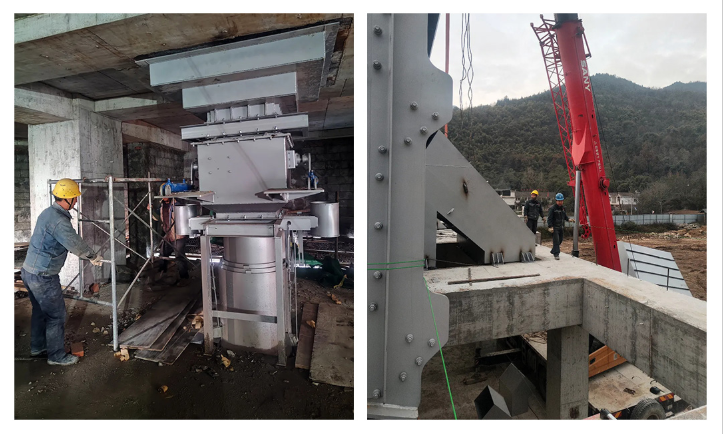

The Beichuan project is progressing well, with the installation of auxiliary machinery and non-standard products successfully completed.

General Manager of Party A and his party visited the site for inspection and guidance, focusing on safety inspection and organizing a work summary meeting for management.

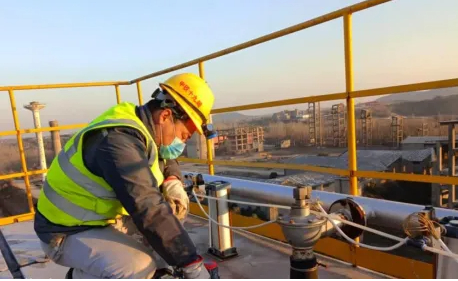

Focus on cleaning environmental protection facilities and maintaining production equipment.

Deployment of pre-holiday inspection, the organization of water source, power supply and all kinds of production equipment comprehensive inspection, to ensure safety and stability during the break.

Adjustment and optimization of screening and conveying equipment, comprehensive inspection of power distribution equipment.

Jiangxi De'an Project Distribution Cabinet and Central Control Cabinet Wiring; Hunan Linxiang Project Corridor Production; Shanxi Hejin Project Lowering and Testing Machine; Shanxi Pingding Project Distribution Room Wiring and Cable Construction.

Promote the R&D project of tracked intelligent bulk material loading equipment according to the plan, and carry out trial production work in conjunction with the workshop field.

Collect process inspection anomaly data, organize and analyze quality inspection records, and establish a consistent definition of quality defects in preparation for FY2025 quality improvement efforts.

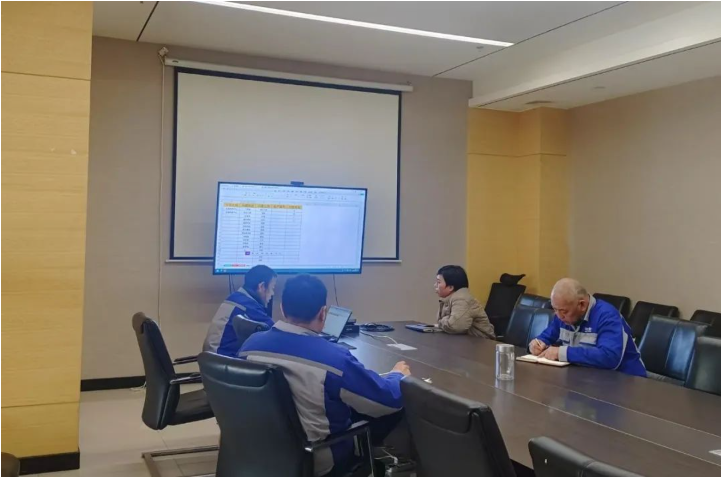

Organize a meeting to comprehensively summarize the recent bidding work problems, propose improvement measures and future planning; organize internal evaluation of excellence, mobilize the preparation of the annual meeting program.

Conducted training on incoming operations and closing of accounts prior to the annual closing of accounts, and discussed adjustments to rules and standards for some subjects in the new year to simplify operations and improve practicality.

On December 31, we participated in the policy seminar of the IITA, which mainly interpreted and mobilized the policies related to specialization, smart factory and high-quality development, and shared the experience of the special training on the upgrading of equipment manufacturing industry clusters of Zhejiang University.

Organize the "2024 Evaluation of Excellence and Precedence Activity", mobilize all centers to recommend advanced materials, and prepare related contents and prizes for the activity.

Preparing the "2024 Annual Commendation and Cultural Evening", finalizing catering arrangements, collecting programs, contacting teachers, and preparing rehearsals.

Prepare the meeting agenda, set up the venue, and collect and organize materials for the 2024 Debriefing and Work Summary meeting.

Arranged equipment shipment for Hunan, Guizhou and Chongqing projects on schedule, and conducted bidding and order evaluation.