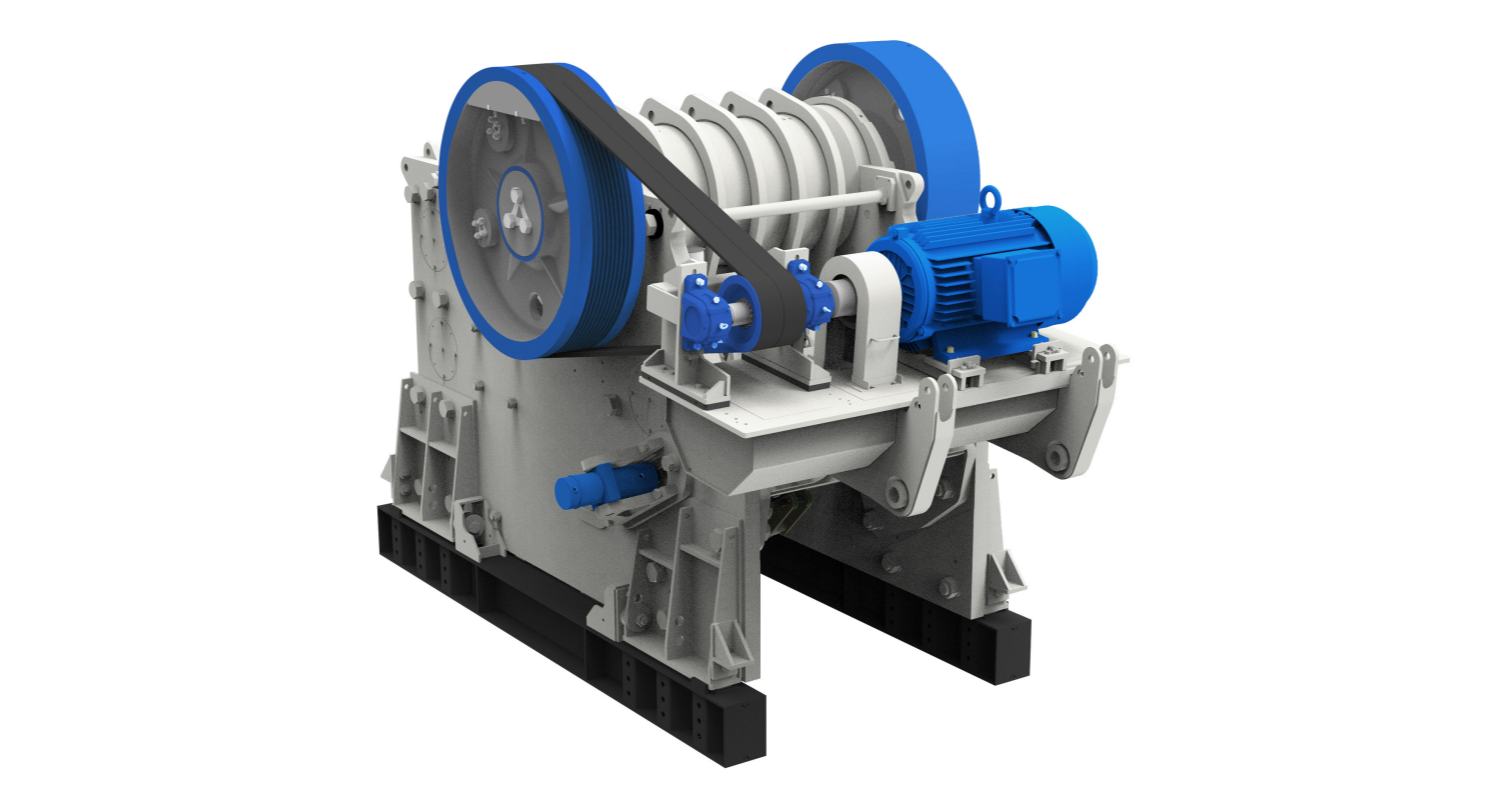

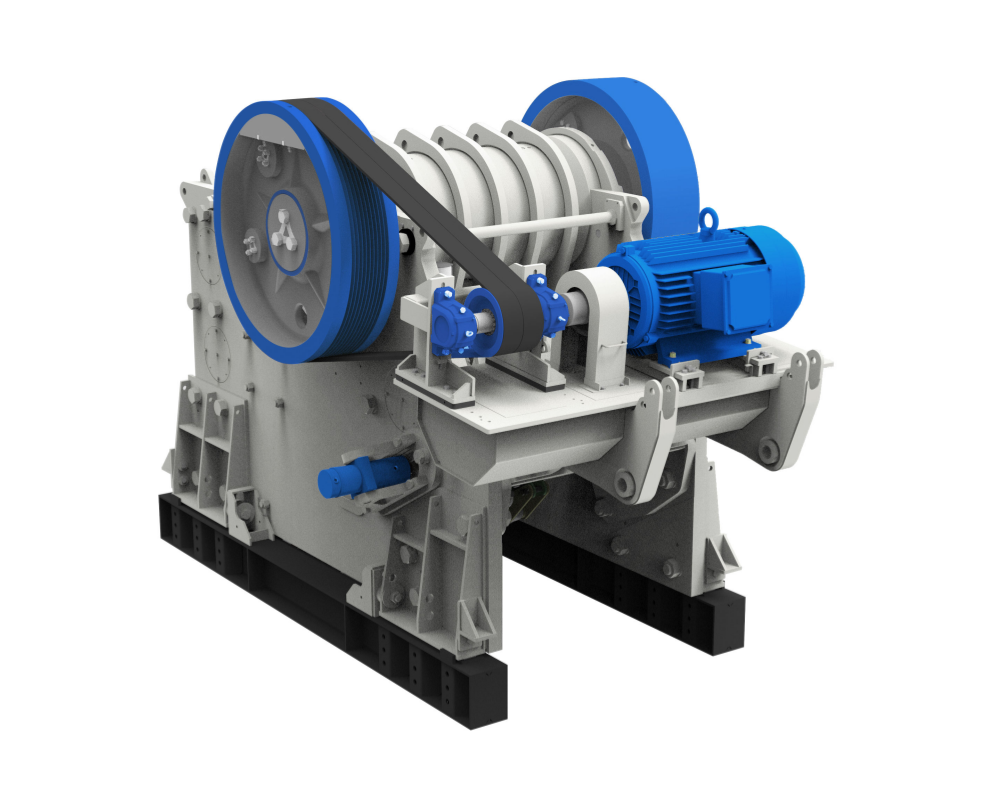

Primary Jaw Crusher Production Line

A jaw crusher, or jaw stone/rock crusher, is a common coarse crushing machine that squeezes materials between a moving and stationary jaw. Used in stone crushing, sand making, and mineral processing, Zhongyu Dingli's DLEV series features a deep cavity design to prevent blockages, increase feeding capacity, and produce uniform products.

| Parameter | DLEV106 | DLEV125 | DLEV160 | DLEV200 |

|---|---|---|---|---|

| Feed Opening (mm) | 1060×700 | 1250×950 | 1600×1200 | 2000×1500 |

| Max Feed Size (mm) | ≤600 | ≤800 | ≤1000 | ≤1250 |

| Discharge Gap (mm) | 60–250 | 75–275 | 120–300 | 135–350 |

| Motor Power (kW) | 110 | 160 | 250 | 400 |

| Capacity (t/h) | 155–500 | 240–760 | 420–1100 | 620–1500 |

The 4,000 tons per day sand and gravel production line is a newly built project designed to produce aggregates such as 12, 13, and 05 stone. Construction started in October 2017, with a total construction period of 45 days.

The large-scale aggregate production line in Yichang, Hubei has a total investment of RMB 60 million and covers an area of 53.73 mu (≈3.58 hectares). The project adopts a fully enclosed environmentally friendly design and is equipped with our DLPCZ1815 heavy hammer impact crusher, DLPC1220 shaping crusher, and other mining equipment.

This project is a newly constructed large-scale aggregate production line completed and put into operation in 2017. The designed capacity is 1,000 tons per hour, with a maximum output reaching 1,500 tons per hour. The production line mainly processes limestone into 0–5 mm, 12 mm, and 13 mm aggregates.

This project adopts a wet sand-making process, which provides excellent dust suppression. Soil and stone powder are washed away during production, resulting in high-quality finished aggregates and manufactured sand.

We are a manufacturer and trading company whose products are sold to domestic and international markets.

We usually make a quotation within 24 hours of receiving your inquiry. You can show us what you need, or we will give you suggestions based on your needs.

Yes. Please feel free to contact us.

It depends on the machine you need. RTS machines will be shipped within 7 days and custom machines will be shipped within 30–90 days depending on the machine specifications you need.

T/T, Western Union, MoneyGram and PayPal. This is negotiable.

Can be shipped by sea, air or express (EMS, UPS, DHL, TNT, FedEx, etc.). Please confirm with us before placing your order.

Yes, please tell me the destination port or address. We have a lot of experience in transportation.