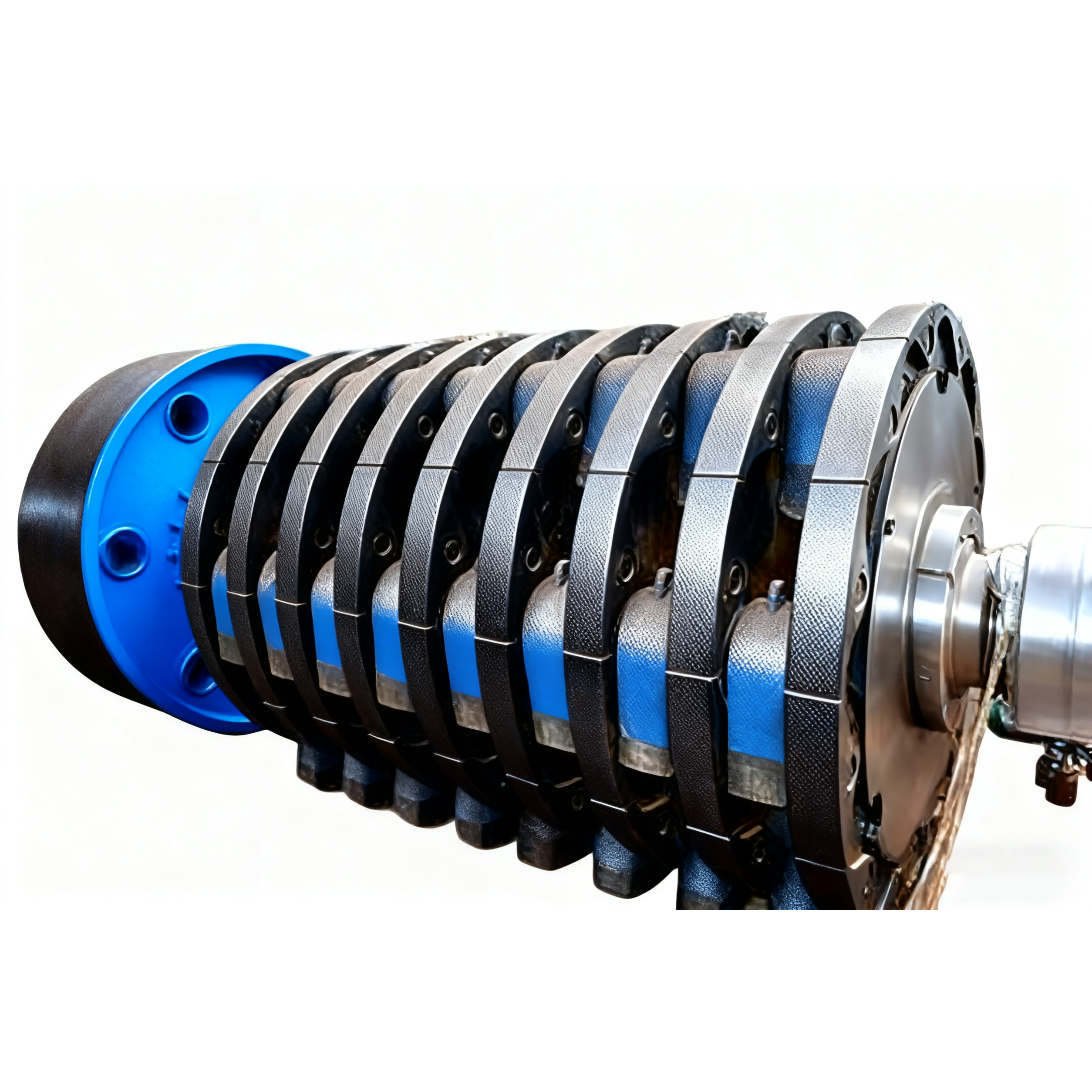

A hammer crusher consists of components such as a pulley, bearing housing, shaft fixing disc, rotor, spacer sleeve, and main shaft. The rotor with the hammer heads is its main working part.

Rotor hammer edges wear under impact, but Xinxiang Dingli’s protective rings allow easy replacement, extending rotor life without changing the rotor.

Protective ring technology extends rotor life, solving issues like short lifespan, damage, low output, and coarse particle size.

Improvements in the casting process have increased the impact resistance of the hammer handle and the wear resistance of the hammer head.

Conact Us

Rotors are usually made from high-strength steel, alloy steel, or chromium-manganese composite, providing excellent durability and wear resistance.

The rotor spins at high speed, and the attached hammers strike the material, breaking it into smaller pieces. Output size depends on hammer size, rotor speed, and screen mesh.

Protective rings are replaceable edges on the hammer disc that prevent rotor wear. When worn, they can be easily replaced by unscrewing bolts—no need to replace the entire rotor.

Yes. Rotors can be customized in diameter, hammer type, material, and protective features to meet specific crushing requirements.

T/T, Western Union, MoneyGram And Paypal. This Is Negotiable.

Yes. Please Feel Free To Contact Us.

Budweiser Ave, Tangzhuang Town, Weihui City, Xinxiang, Henan, China

+86-18827272727

Welcome your inquiry, we will reply you within 12 hours after receiving the email